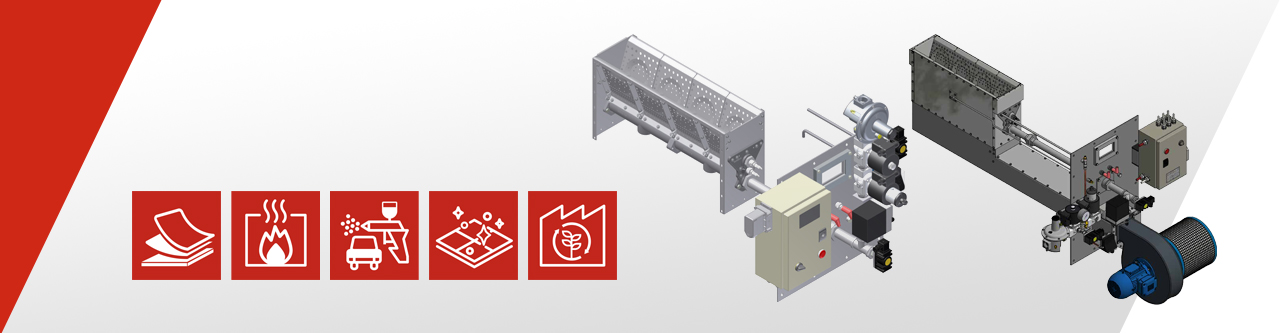

DBO, DBC

“Open Back” and "Close Back" Monobloc Air Duct Burners

The air-draught burners series “DBO” is used in all those applications where it is required the direct heating of large quantities of air with small increase of temperature.

In this type of burners the combustion air is the same as the process air, and it is taken through the mixing head, by a suitable reduction of the duct section. The increase in speed resulting from the reduction of the duct section allows to have a correct and complete combustion.

The application of this kind of burner is possible only when free oxygen is higher than 19% and when in the process air there are no solvents nor other gases in such a concentration to cause uncontrolled combustion reactions.

This type of heating has an efficiency of 100% because the whole combustion energy is transferred directly to the process (direct exchange combustion).

This direct exchange gas burners series is extremely flexible and can be installed in a large number of industrial processes.

The burner consists of a plate to which the mixing head is fixed (positioned in the centre of the duct).

Outside the plate there are the control board with flame control equipment, the interception and regulation gas train and the flame detector.

The mixing heads have a modular design to obtain a distribution of the power on a surface suitable to allow a correct mixing with the process air.

The installation must be done to give a speed of process air of 20 m/s with a pressure drop of approximately 2 mbar.

“Close Back” version of the ELCO duct burner range is also available.

FEATURES

- Direct spark ignition or indirect by gas pilot integrated on the burner module

- Ionization flame detection by electrode or by UV cell

- Combustion head for natural gas (LPG or other fuels on request)

- Turn down ratio 10:1

- Available with thermoregulator

- Available as packaged execution, with gas train according to EN 746-2 (or other required)

- Easy to install, start and operate